The Challenge

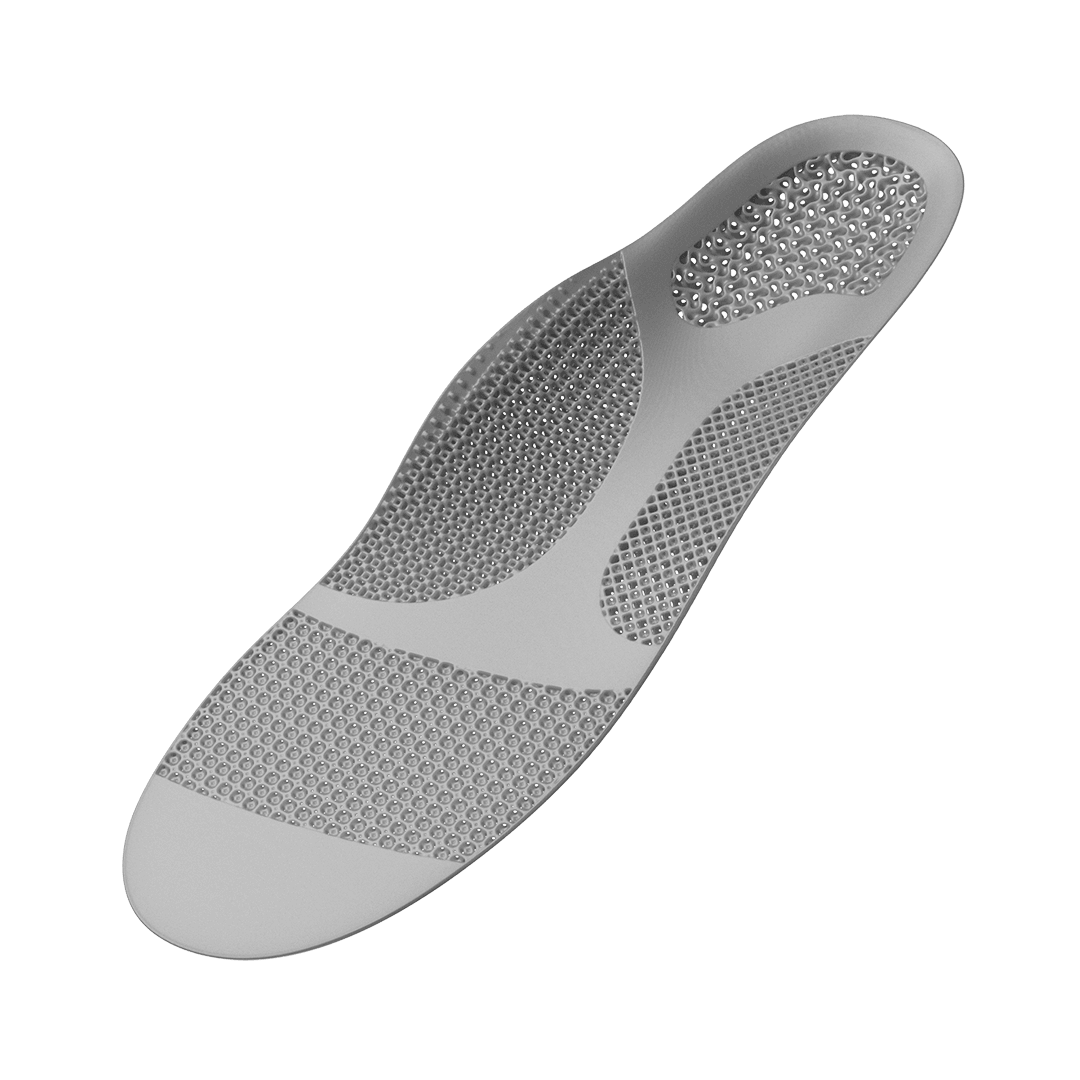

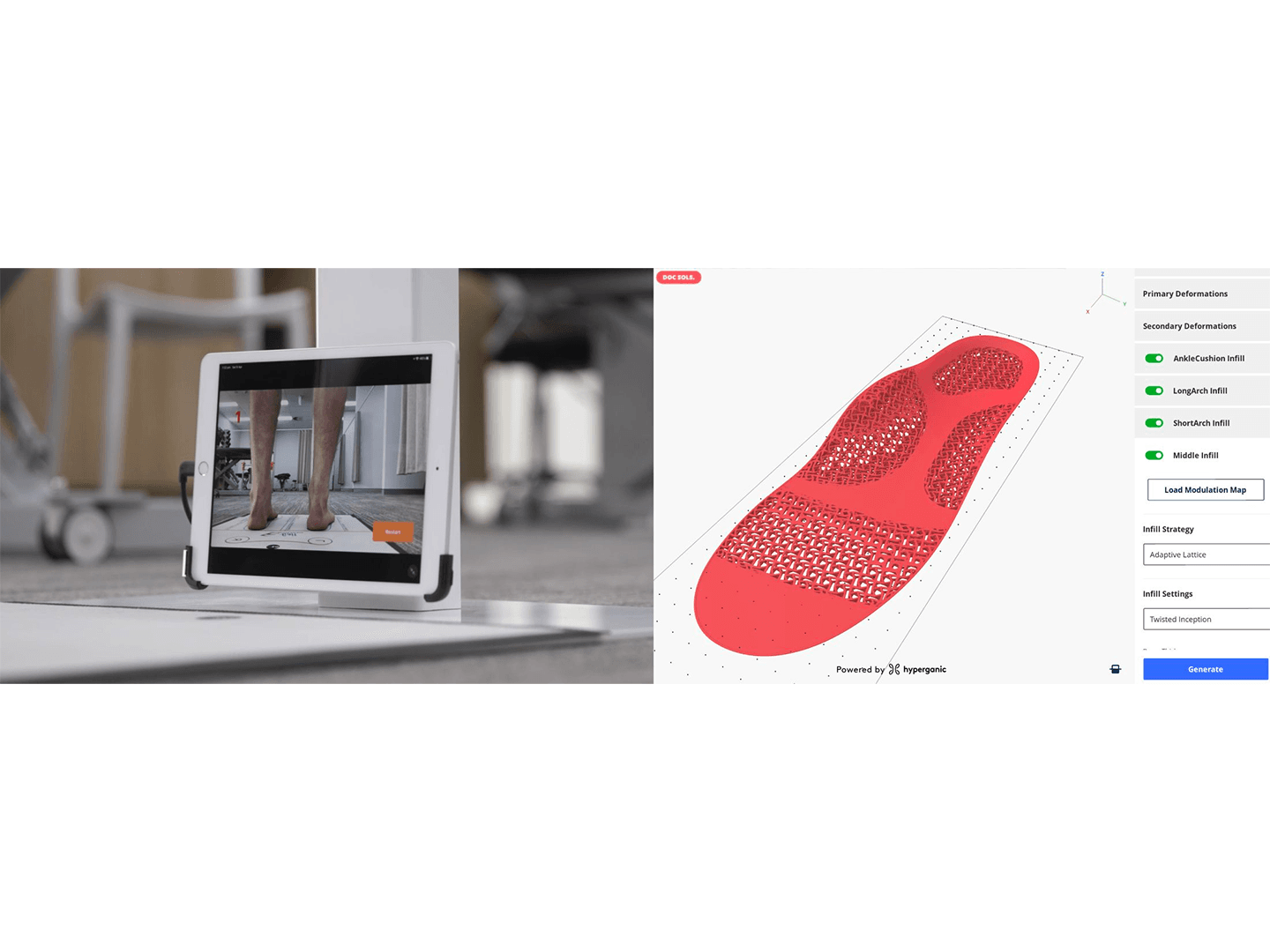

Traditionally, the manufacture of custom insoles has been time-consuming and material-intensive, as the process of milling thermoplastic or EVA materials often resulted in orthotics with uniform density and limited design flexibility. However, with the advent of 3D printing, it is now possible to embed various mechanical properties directly into a material, offering customization and precision that was previously challenging to achieve. This case study examines how the partnership between Hyperganic and Elite Orthotics, an Australian Podiatry Clinic, opens up a new frontier in the field of orthotics.