The Challenge

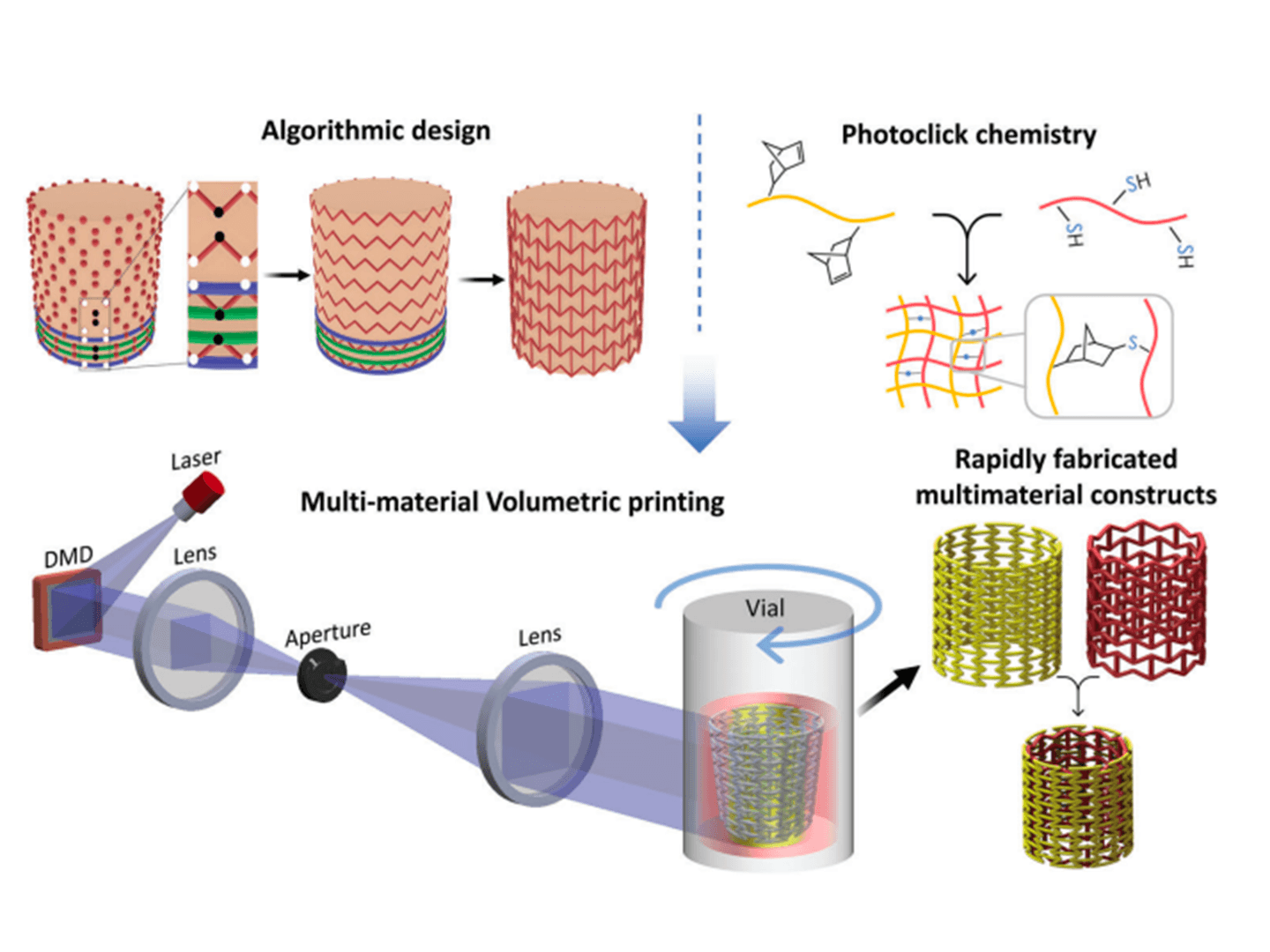

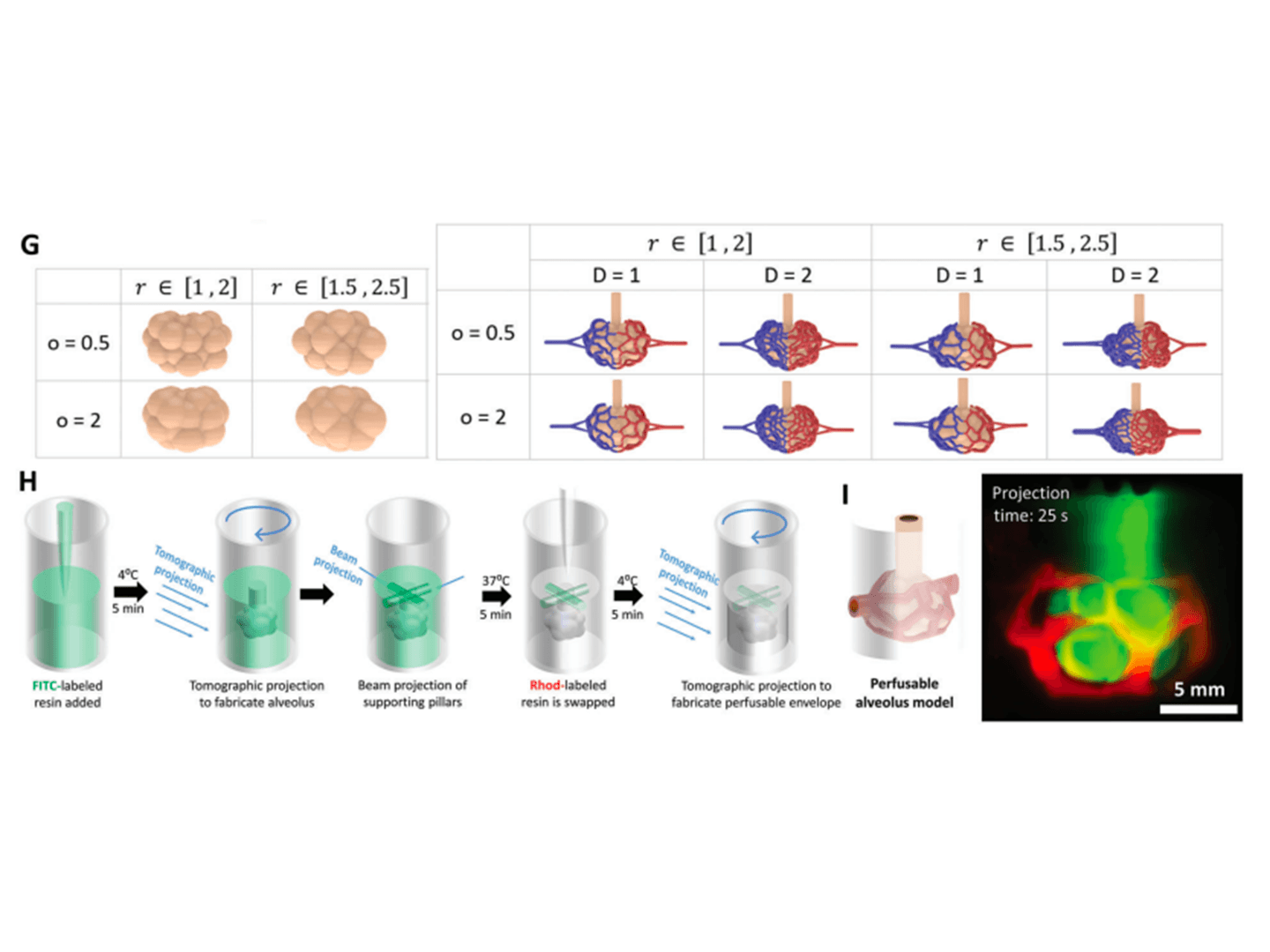

Traditional additive manufacturing methods are limited in their ability to produce intricate structures with tailored mechanical properties. Recognizing this challenge, Hyperganic collaborated with the Department of Health Sciences and Technology at ETH Zürich University to overcome the complexities inherent in designing and fabricating constructs for biomedical purposes.